what is shore hardness test|durometer scale comparison chart : broker Definition of Shore hardness testing. The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240. In the Shore hardness test, the . web27 de mai. de 2020 · Through the integration of the LOQR’s platform, which ensures the Client’s virtual presence in full compliance with the KYC, AML, and Contract Signature Guidelines, the Online Account Opening for Organizations process is carried out in three steps and in less than 20 minutes, the account is active and ready to operate, and access .

{plog:ftitle_list}

A vacina penta (DTP/HB/Hib) - vacina adsorvida difteria, tétano, pertussis, hepatite B .

shore hardness vs durometer

The Shore A hardness scale is a method used to characterize how resistant materials are to localized deformation or indentation. It is one of many scales used to measure the durometer (or hardness) of a material, . Shore Hardness, using either the Shore A or Shore D scale, is the preferred method for rubbers and thermoplastic elastomers – and is also .

Definition of Shore hardness testing. The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240. In the Shore hardness test, the .

measurement of fluid film thickness

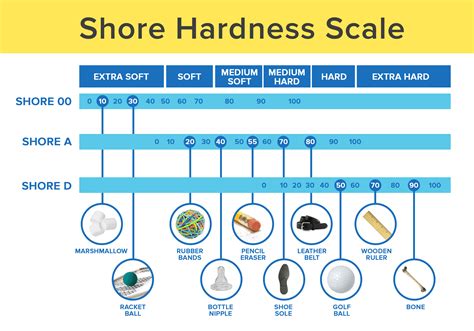

Shore hardness is a measure of a material’s resistance to indentation, which provides an indication of its stiffness or flexibility. The Shore hardness test is performed using . What is the Shore D Hardness Scale? The Shore D Hardness Scale is a method and reference system for measuring the hardness of materials such as rubber and plastic with a tool called a durometer. The exact .The Shore hardness scale is commonly used to test the hardness of soft rubbers, rigid plastics and supersoft gels. Shore hardness is tested with an instrument called a Durometer, which .What is Shore D hardness? The Shore D Hardness test is also called Durometer Hardness Test. The letter "D" symbolizes the type of durometer used to measure the hardness of a .

Shore hardness measures the level of resistance a material demonstrates against indentation pressure. The device used to perform this test is known as a durometer. Durometer devices measure the depth of indentation created in . Durometer Testing. The hardness of elastomeric materials comes down to one component: the depth that a spring-loaded indenter penetrates through the specimen. The softer the specimen, the farther the indenter will .

The Shore D hardness scale is a test method that determines the hardness of a material. Learn more about it here. . and when it comes to rubber and hard plastics, look no further than the Shore D Hardness scale. With the . Determining the hardness of a material can be done by using a durometer tester. In this video, we demonstrate how to use this device with different types of .

Shore Hardness Testing and Scales. An o-ring’s durometer is the measurement of that specific material’s hardness. This scale is also measured by an instrument called a durometer gauge, which uses a spring-loaded rod to . Shore Hardness (HSD) Shore hardness measures the hardness of non-metallic materials by evaluating the material’s resistance to a specific indenter shape. Shore hardness values can be converted into other hardness units. Note: In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. Filaflex FOAMY, has a Shore hardness of 78A, but thanks to its dynamic foaming technology, it can reach a Shore hardness of 51A. It is an ideal filament for printing elastic and lightweight parts, reducing their weight and density. Filaflex 70A, 'Ultra-Soft', with a Shore hardness of 70A, is a highly elastic filament with a 900% *elongation. What is shore hardness? Shore hardness is the measure of a particular material’s resistance to penetration or indentation. Basically, it tells you how hard a material is and how much force it can take. The Shore hardness scale was invented by Albert Ferdinand Shore in around 1920 and has been used ever since. How is shore hardness tested?

Dr. Dmitri Kopeliovich Shore hardness is a measure of the resistance of a material to penetration of a spring loaded needle-like indenter. Hardness of Polymers (rubbers, plastics) is usually measured by Shore scales. Shore A scale is used for testing soft Elastomers (rubbers) and other soft polymers. Hardness of hard elastomers and most other polymer .Shore hardness testing is typically performed following ASTM [19] standards. The two most common test procedures are the Shore A and the Shore D scales. The Shore A scale is used for “softer” rubbers while the Shore D scale is used for “harder” ones. Other Shore scales, such as Shore O and Shore H hardness, are used less often.

Shore Hardness Testing: Uses the principle of measuring the resistance of a material to indentation; Advanced Techniques in Hardness Testing Methods . Some advanced hardness testing methods include: Leeb rebound hardness test: Measures the velocity of a moving object in the free rebound method;

Answer: d Explanation: Most widely used hardness test is a Rockwell test in the US. It is because of the fast speed. It gives a small indentation.

Shore Hardness Test: Specifically designed for elastomers and plastics, this test measures the material’s resistance to indentation using a standardized indenter. It’s crucial for assessing materials like rubber or silicone. . Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard .Brinell Hardness Test: Rockwell Hardness Test: In Brinell Hardness Test the indenter is a spherical Tungsten Carbide Ball: For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC) Hardness greater than 650 HB can not be measured with the Brinell Scale setup. There is no such limitation in Rockwell .To perform a Shore hardness test, a durometer gauge featuring a spring-loaded steel rod will compress the surface of a material and provide a reading of the resulting indentation. Performing a Shore hardness test involves three basic steps: Step 1.Ideally, the material under test should be a minimum of 6.4mm or .25 inches to ensure accuracy. The term durometer is often used to refer to the measurement as well as the instrument itself. The durometer scale was defined by Albert F. Shore, who developed a measurement device to measure Shore hardness in the 1920s.

Shore Hardness is a measure of the resistance of a material to penetration of a spring loaded needle-like indenter. Hardness of polymers (rubbers, plastics) is usually measured by Shore scales. Shore A scale is used for testing soft .The PCE-DDO 10 durometer is an ergonomic device to check Shore hardness in gum. It has been designed with a high quality. The PCE-DDO 10 durometer is mainly used for soft gums. If the material thickness is not enough, it should be tightened on the back with the same material in order to increase its thickness.The Shore Hardness scale is a universal scale for measuring and communicating the hardness of a material, including rubbers and plastics. . 4 Additional Considerations for the Shore Hardness Test Let’s take a minute to .

The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test force >= 49.03 N), more precisely with a test force of 29.42 to 1471 N. It is a differential-depth method. Why is the Shore hardness test used? Shore hardness is a measure of the resistance of a material to penetration of a spring loaded needle-like indenter. Shore A scale is used for testing soft Elastomers (rubbers) and other soft polymers. Hardness of hard elastomers and most other polymer materials (Thermoplastics, Thermosets) is measured by .

What does the Shore hardness scale typically test? The Shore hardness scale is commonly used to test the hardness of soft rubbers, rigid plastics and supersoft gels. Shore hardness is tested with an instrument called a Durometer, which has a foot that is inserted into the material being tested. The foot is spring loaded and it is the spring . Record the Shore hardness value. The test method is the same no matter what Shore hardness scale is used. What Is a Durometer Scale. A durometer scale is a classification that describes the hardness of different materials that are grouped together based on similar attributes such as rigidity and flexibility. Some hardness (durometer) scales .

What is the Shore Hardness Scale? The Shore Hardness Scale, created by Albert Shore in 1920, quantifies hardness from 0 (the softest and most flexible) to 100 (the hardest and most brittle) for various materials. Resins are measured on the Shore D scale for rigid materials (as opposed to Shore 00, Shore A, Shore B, etc, which are used for other . Objects such as wood, which can be easily scratched, have a lower hardness compared to steel or granite, since it is difficult to scratch them. How to measure the hardness of a mineral. There are numerous tests to measure the hardness of any material, such as the Knoop test, the Rosiwal test, the Shore test and the Roswell test (in its two .

The Barcol hardness test is generally used on soft materials such as rigid plastics. It measures hardness based on indentation of a sharp point with a flat tip. The test is performed using a similar method and indentation device as that used to measure Shore D hardness, however the Shore D indentor has a round tip. [4]

Common Hardness Scales: Shore A: Ideal for softer materials like rubber, neoprene, and PVC. Shore D: Used for harder materials like rigid plastics and leather. Applications of Shore Hardness Testers: Quality Control: Ensuring products meet specified hardness requirements. Research and Development: Studying the effects of different materials and manufacturing .The Shore hardness measurement is a test method used to evaluate the surface hardness or elasticity of a material. This measurement is used to determine the physical properties of a material, to carry out quality controls or to check the compliance of a material. The Shore hardness measurement is conducted by means of Shore hardness gauges or .In which hardness testing method does an experienced operator test the material by scratching the surface?, 3. Which hardness testing method uses a 15N Scale? and more. . Shore Scleroscope. 17. In which two hardness testing methods is the depth of penetrations measured, rather than the width of penetration? Rockwell & Rockwell Superficial.

measurement of gear tooth thickness by gear tooth vernier caliper

4 dias atrás · Atlanta, capital city of the U.S. state of Georgia. It lies in the foothills of the Blue Ridge Mountains in the northwestern part of the state, just southeast of the Chattahoochee River. It is Georgia’s largest city and the principal trade and transportation center of the southeastern United States.

what is shore hardness test|durometer scale comparison chart